The idea of a closed-loop system

In the innovative economy of the 21st century, businesses are adopting strategies based on the Circular Economy - the reuse, processing, and recovery of materials, creating closed production cycles. This is not only a step towards the future but also an attractive prospect for companies that aim to operate in a sustainable and socially responsible manner.

rPET - Recycled PET from the recycling process

Carbon footprint reduction: Utilizing rPET instead of traditional PET results in a decrease in greenhouse gas emissions. The production of rPET requires significantly less energy and emits less CO2 compared to the production of plastic from primary raw materials. As a result, companies can substantially reduce their carbon footprint and contribute to the fight against climate change.

The use of recycled products represents a crucial step toward achieving zero greenhouse gas emissions. Companies actively involved in a circular economy contribute to waste minimization and the efficient use of resources, enabling them to pursue the goal of zero emissions and sustainable development.

As part of our commitment to full transparency and environmental responsibility, our company has implemented the RecyClass Recycling Process Certification, in accordance with the standards EN 15343:2007 and ISO 22095:2020. This certification confirms the quality of our recycling processes and the transparent origin of the recovered materials we use.

The RecyClass audit program allows for verification of the source of waste and confirms that the recycled raw materials meet the highest quality standards. Through this certification, we build trust among stakeholders across the plastics value chain and support the development of a circular economy by promoting the conscious and responsible use of plastics.

Obtaining the RecyClass certification is another step toward achieving our sustainability goals, minimizing environmental impact, and delivering products to our customers with verified material origin.

Environmental responsibility: The use of recycled products demonstrates a company's commitment to environmental protection. These actions align with the global effort to reduce the consumption of natural resources and minimize waste, contributing to the preservation of nature and biodiversity.

Brand image: Companies that consistently use recycled products build a positive brand image among consumers who increasingly expect businesses to take environmentally friendly actions. Focusing on sustainable development and combating climate change can attract loyal customers, enhance brand trust, and contribute to the long-term success of the company.

Efficient resource utilization: Utilizing rPET as a raw material enables companies to efficiently use available resources. Through recycling, plastic waste becomes a valuable material for producing new products. By minimizing waste and optimizing material usage, companies can achieve greater efficiency in resource management, leading to cost reduction and increased profitability.

All these benefits contribute to the positive impact that the use of recycled products, such as rPET, can have on the operations and development of businesses. Transitioning to more sustainable production models and utilizing recycled materials is not only a responsible approach but also a strategic business decision, yielding long-term benefits for both companies and the natural environment.

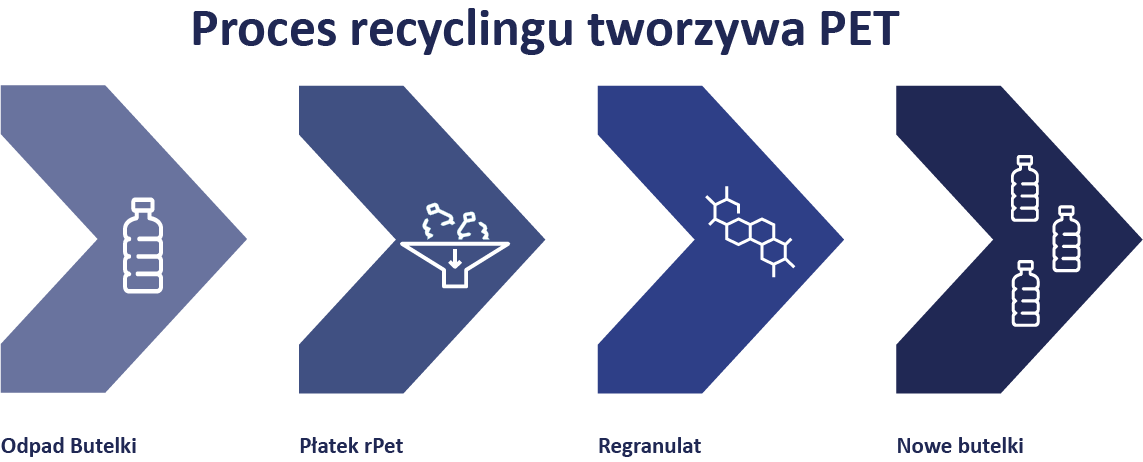

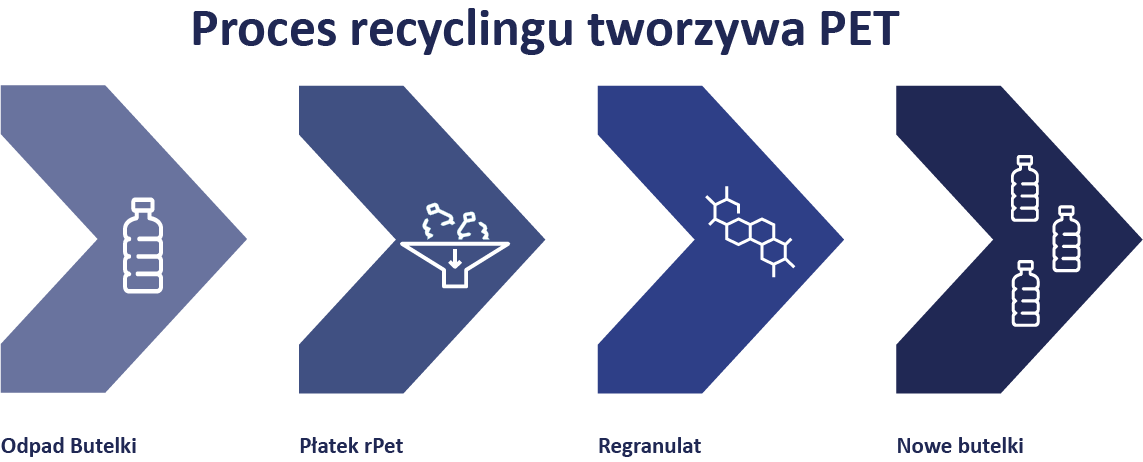

The process of producing rPET flakes begins with the collection and segregation of plastic waste, including PET bottles. These collected plastic raw materials are then processed in specialized recycling facilities.

Creating PET flakes from recycling is a significant step towards sustainable production and reducing the consumption of natural resources. Through recycling, plastic waste can be utilized as valuable raw materials for the production of new products, decreasing the need for extracting new resources and limiting the negative impact on the environment. Simultaneously, such actions contribute to increased economic efficiency and create business opportunities within the circular economy.

The process of producing rPET flakes begins with the collection and segregation of plastic waste, including PET bottles. These gathered plastic raw materials are then processed in specialized recycling facilities.

In the case of recycled PET flakes, the most commonly used method is mechanical processing. First, the collected PET bottles are sorted and any unwanted elements such as caps, labels, or other contaminants are removed. Then, the bottles are shredded into smaller pieces and subsequently ground into a fine powder.

After obtaining the PET plastic powder, the cleaning and recovery process follows. The powder is subjected to special processes, such as washing, rinsing, and removing residues of other substances. As a result, a clean, granulated PET material is obtained, which can be reused in the production of new products.

Subsequently, the recycled PET granulate (rPET) can be processed into various products, such as packaging, textiles, or bottles. The injection or blow molding process is often used to form these products from rPET. At this stage, the granulate is heated and formed using special molds to produce the desired shapes and sizes.

By utilizing recycled products, such as rPET flakes, companies gain a sustainable competitive advantage. Operating in line with the principles of a circular economy allows firms to minimize their negative impact on the natural environment while creating innovative solutions that distinguish them in the market. This approach attracts environmentally conscious customers, strengthens market position, and opens up new business opportunities.

Rising environmental awareness is a clear trend among consumers at large. Customers increasingly prefer products with a low environmental impact, and companies are responding to these expectations by introducing more sustainable and eco-friendly solutions. Examples include businesses offering clothing made from recycled materials or utilizing biodegradable materials in packaging.

The consumer is increasingly interested in participating in a closed-loop system, returning, and reusing products.

A circular economy not only contributes to environmental protection but also creates new business opportunities. Companies that implement innovative solutions related to material recovery and processing can discover new markets for their products. Actions taken by businesses, both individually and as part of larger industrial initiatives, have tremendous transformative potential and contribute to building a more sustainable future.